SPECIFICATIONS

Combinational Telecom Shelter

Multi-function cabinet (shelter) has developed special fabrication techniques for creating tough and durable cabinets and shelter for the market of outdoor telecommunication and networking.

The product series was recently launched with much success and enthusiasm and provide platforms for a very broad range of outdoor operation needs.

Assembly or PU foam shelter originates from the demand of mobile communication network construction.

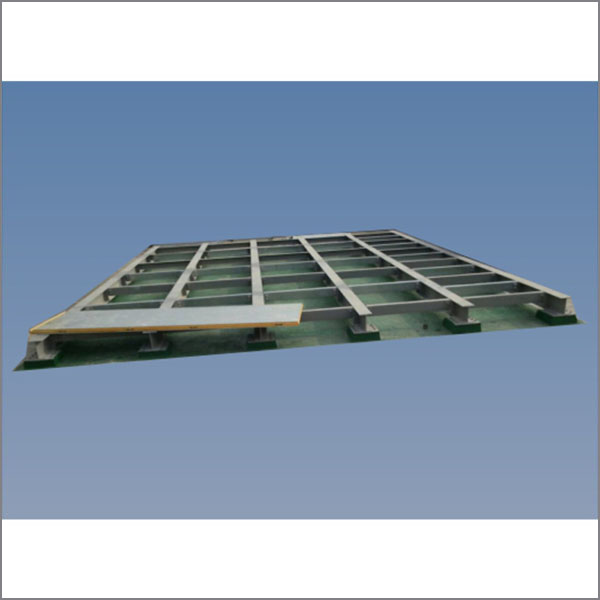

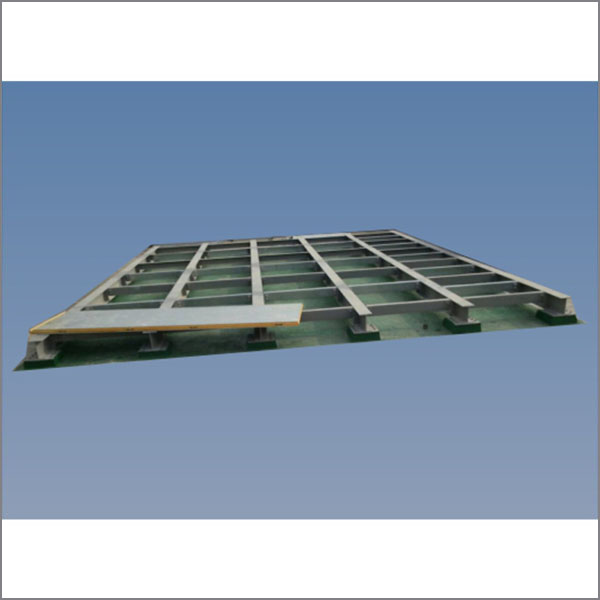

These shelters are manufactured using sandwich panels constructed with composite PU foam and beam configuration.

Panels are made of hot bonded sandwich construction consisting of PU foam core, metal panel and framework of welded aluminum alloy extrusion. These shelters can be moved via land, air or sea.

This construction technique combines strength and rigidity with a high degree of environmental protection.

The cabinets have fire-resistant character. The structure is not the combustion materials. This board is modular cabinets, made by molding in the factory, the quick connectors easy to be assembled at the construction site.

Summarizing above points, PU foam shelters could be more effective to take advantage of and meet the needs of each company’s policy.

Our shelters are made by special steel and insulated materials and anticorrosive powder coating, weather resistance, anti-rust and corrosion.

More than ten years of life-span under normal using

Feature:

- Integration

It needs sufficient space to accommodate the base station equipment required: as BTS, power plate,SMR, transmission equipment, air conditioning equipment, monitoring and fire protection equipment etc.

- Mobility, Convenient and flexible installation

Easily assembled, installed cabinets in the base station, you can migrate the entire installation or dismantling to other where.

- Security

Non combustion materials, waterproof, windproof, shockproof, protective (anti-theft, anti-sabotage).

- Good adaptability for the field environment

It could be installed into peripheral equipment such as power, ground, air conditioning, environmental monitoring and ventilation.

Construction & Specification:

| Ingress Protection |

Up to IP55. |

| Airtight/Waterproof/Windproof/Shockproof: |

Silicon used on the joints for panel connection to enhance waterproof result. |

| Shockproof ability: |

Up to 6 magnitude earthquake. |

| Windproof ability: |

Can be blow with up to 60 M / sec of wind, and without any damage caused. |

| Waterproof ability: |

Shooting with water hydraulic 1kg / cm ^ 2 and no interpenetration. |

| Fire resistance: |

Non-support combustion material used-Adiabatic material (PU) and PVC galvanized steel for both inside and outside.

Conform to heat-resistant CNS- 7774 specification and building material combustion performance GB8624-2006. |

| Antirust ability: |

Hot-dip galvanized treatment for exposed steel which will last longer than ten years. |

| Airtight ability: |

Inside and outside cabinet all conform to airtight needs. |

| Load capacity: |

1.6T / m of average load, 3T of centralization load. |

| Heat insulation: |

PU heat-insulation density up to 42kg / M3. Overall coefficient of thermal conductivity is between 003Kcal /MH C.

Certificated per academic institution. |

| Interval of door panel and door frame: |

Provided construction security. |

| Features of door and door frame: |

Same heat-insulation for all cabinet doors, side panels, and top panels.

Dimension of door, door position and opening direction can be made according to customer requests. |

| Cable instruction: |

Create according to customer request and provided with a waterproof stainless steel plate for cable install. |

| Cabinet assemble: |

All series can be assembled locality, 2-3 laborer a time and assembling within 2hrs. |

| Maintenance: |

Maintenance: Any maneuverable design which can be assembled or disassembled locality, and good condition for parts replacing.

(Such as door and door frame set..etc). |

Modular correspondence server center which means a layered combination server center, it’s a rapid assembly modular design that apply on any assembly environment.

Or it can be delivered with a complete cabinet after well assemble in factory.

All plate material of six sides of this combinational shelter is composite structure which internal and external layers are zinc-plated steel plates with PVC coated processed.

The middle layer is filled with PU and pre-buried with C steel as part of the structure.

The purpose is not only to reinforce the rigidity of the plate, but also to add hanging hook for fixing function.

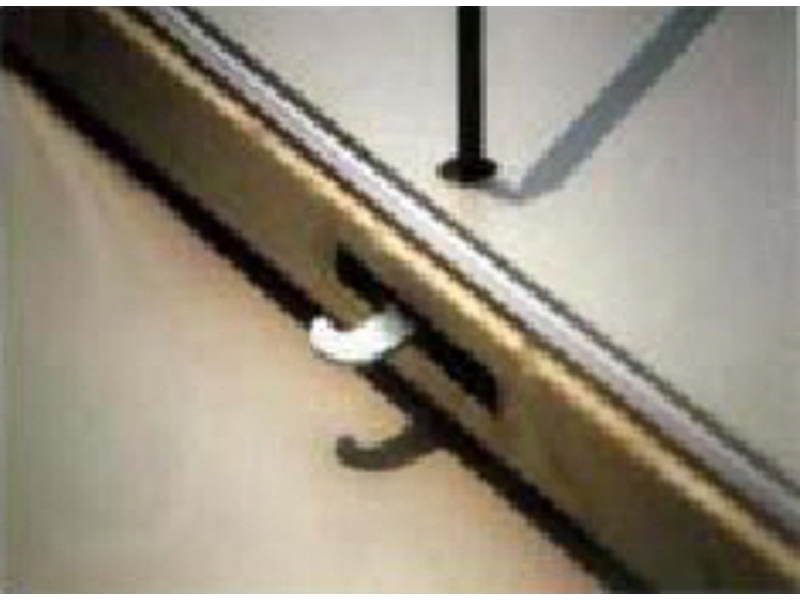

The purpose we use steel for structure base in the lowest layer of combinational shelter is to evenly distribute the weight carried, so that it can be used to carry floor plate which has worse weight carried.

Our steel structure base can carry the average load of 1.6T/M² and 3T of centralized load.

The shelter plate on the top is two-piece type formed into one piece. The entire roof only has one joins where there is an additional Al material cover plate used as an reinforced protection for leak-proof.

Operation:

(A) The location of exterior machine of the air conditioner can be flexible changed according to station’s surroundings.(B) The hole-site can be set up at the front, rear, left orright side according to the station’s surroundings.

Opening of cable:

(A) At the narrow wall of combinational shelter, two holes are opened respectively (four holes totally), and each hole can contain more than six (included) 7 / 8" cables.

(B) It must has waterproof pair-lock type steel plate to be used as fixing purpose of hauling cable, meanwhile, it has cable guided hole of disassembly type compressiv insulated protective barrel.

Install & Application:

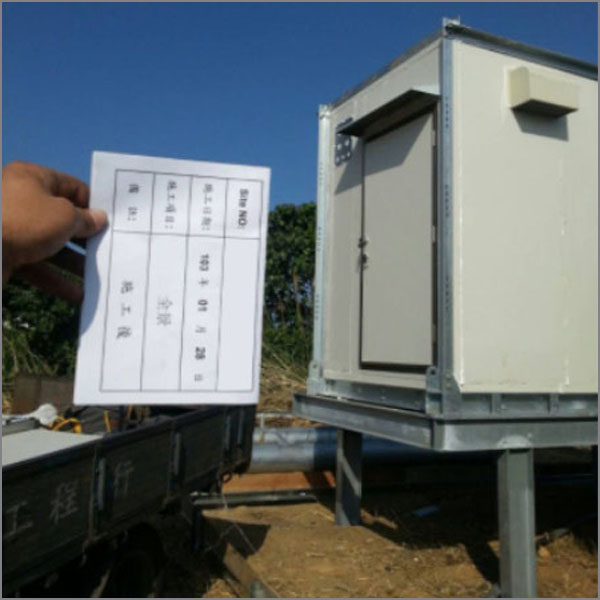

model:Shelter

Shelter

DOWNLOAD